- INTERTECH TECHNOLOGIES PVT. LTD.

Engineers to Healthcare Industry®

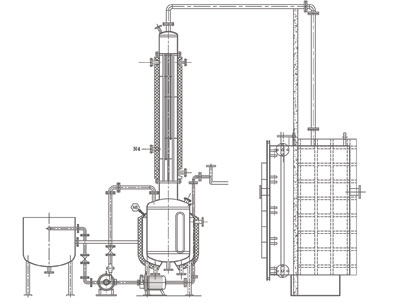

VACUUM TRAY DRYER

|

| |

CONSTRUCTION DETAILS

Overall body is made of suitable thickness SS Plate with optional SS304Q or SS316Q. This equipment is normally floor mounted & flushed to wall so that operation can done from production area & services from technical area. There is option of hot water circulation by limped coil for outer body to avoid dew / moisture formation on the internal chamber of the dryer. Option of providing receiver condenser or vacuum pump to recover the harmful chemicals or expensive solvents.

Maximum contact surface for efficient heat transfer to product by giving flattened bottom of the trays & top plate of heating shelves. Heating shelf are hollow pad type of suitable thick top and bottom welded on all joints with a n annular space welded on all joints. Provision of SS baffle in annular space to guide flow of heating fluid to ensure full coverage of heat transfer area and for uniform heating. Longer & durable heating pad plates made from thick SS sheet fully argon arc gas welded & provided with S.S.304Q square rod stiffeners. For better, quick & easy maintenance heating pad plates connected to main inlet / outlet header with tri-clover fitting from out side the chamber. Gap between two heating pad plates as well as body walls ensures that condensate on side walls do not fall back in to the product trays. Provision of sight & light glass give product inspection without disturbance. Hinged ‘C’ clamp with knobs all across the door to avoid leakages.

DIMENSIONAL DETAILS (in mm) |

| MODEL |

A |

B |

C |

D |

E |

F |

| VTD - 06 |

865 |

550 |

1000 |

985 |

685 |

1800 |

| VTD - 12 |

865 |

950 |

1000 |

985 |

1085 |

1800 |

| VTD - 24 |

890 |

925 |

1700 |

1250 |

1085 |

2100 |

| VTD- 48 |

1675 |

950 |

1760 |

1790 |

1085 |

1960 |

Technical Specifications |

| MODEL |

VTD - 06 |

VTD - 12 |

VTD - 24 |

VTD- 48 |

| Batch capacity * Kgs. |

24 |

48 |

96 |

192 |

Steam consumption Kg / hr

(for Steam Heating) |

25 |

50 |

100 |

192 |

Hot water Tank in liters

(for Hot water heating) |

300 |

400 |

500 |

750 |

| Drying Temp. (C) |

60-80 |

60-80 |

60-80 |

60-80 |

* Will vary depending on bulk density of products

OPTIONAL

- CONDENSER

- SILICON GASKET OR EPDM GASKET FOR DOOR

- RECEIVER

- INTERCONNECTING PIPING

- SS TRAYS

- HOT WATER GENREATING SYSTEM

- VACUUM PUMP

- DIGITAL TEMP. INDICATOR

- LIMPET COIL

- CONTROL PANEL

|

|

|

|

|