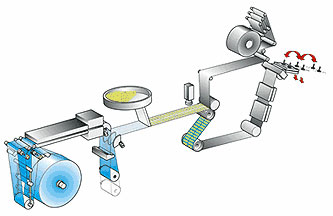

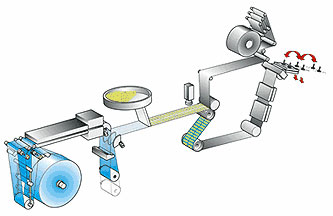

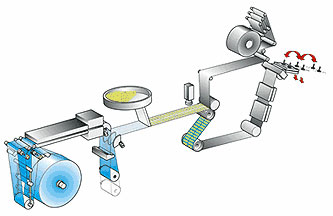

Ampoules and Vials blistering machine

| |

Compressed Air Blister Forming, Intermittent Motion Flat Bed Machine with application for Ampoules & Vials using change parts. These machines are designed for the packaging of syringes, ampoules, vials and small products. With its attractive running speed and very quick size change over, it is the ideal tray-forming solution for small/medium batches or when many batch changes or size changes are required.

Blister packing machine, with flat bed thermoforming, have all the features for excellent performance and are very simple to operate:

- Touch screen PLC for adjusting the operations

- Automatic filling

- Print out of the batch number and expiration date by embossing.

- Camera / sensor system for ejecting all under-filled blisters.

- Easy to change the format and the range of stroke.

- Made with interlocks & with protective covers for safety.

|

|

Technical Specifications |

| Format area |

Max: 300mm x 150 mm (advance) |

| Forming depth |

Up to 32 mm, 20 to 35 cycles/min (depending upon the depth of the product) |

| Base material |

Thermoforming film PVC, PVC/PVDC

Max 440mm x 320 mm |

| Lidding material |

Heat sealable material of aluminium or paper

Max 440mm x 320 mm |

| Power consumption |

Peak power: 11,0 Kw

Average power: 7,0 Kw |

| Air consumption |

Inlet 6-8 Bar

With 10 mm drawing depth

Without plug assist: 270 LTRS/ Min

With plug assist: 410 LTRS/ Min |

| Cooling water consumption |

120 LTRS/HR, 3 Bar, from 100 to 160 C |

| Floor space(LxWxH) |

4750 mm x 1090 mm x 1750 mm |

|

|

|

Workflow