- INTERTECH TECHNOLOGIES PVT. LTD.

Engineers to Healthcare Industry®

DRY HEAT STERILIZER

|

|

| |

|

|

Dry heat can be used to sterilize items, but as the heat takes much longer to be transferred to the organism, both the time and the temperature must usually be increased, unless forced ventilation of the hot air is used. Dry heat has the advantage that it can be used on powders and other heat-stable items that are adversely affected by steam. Dry heat sterilizers are best of Sterilization to reduce microbial burden & De-pyrogenation by way of de-naturing of microbial endotoxins.

|

|

|

|

|

-

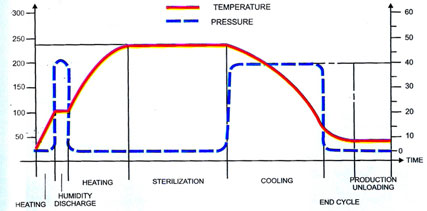

Exhaust phase for moisture removal from the load.

-

Heat up Phase to increase temperature of load from ambient to Sterilization temp.

-

Sterilization Phase is the hold up of temp. for certain time.

-

Cooling phase to cool the load to desired temp. by rapid air convection.

CONSTRUCTION DETAILS:

- All stainless steel cGMP construction or stainless steel interiors & exterior

- Class 100 sterilizers with High Temp. HEPA filters

- Positive pressure through the process for sterile integrity.

- Advanced gasket for positive seal & expansion compensation structure which prevents thermal vibrations.

- Incolloy sheathed heating elements for reduced particle generation & longer life.

- Exhaust flap with pneumatic actuation & specially designed silicone ring seal.

- Special connectors for validation & testing.

- Cooling coils for rapid cooling during cooling cycle

- Electrical door interlocks with visual indication

- Terminals for all electric heaters are outside the working space and are accessible and replaceable from the non sterile side when required

|

Technical Specifications |

CAPACITY OF DRYER IN KGS AT 0.6 KG/KG IN BULK DENSITY |

30 |

60 |

120 |

150 |

200 |

250 |

300 |

500 |

WORKING CAPACITY OF PRODUCT CONTAINER

IN LITERS |

50 |

100 |

230 |

290 |

360 |

475 |

550 |

900 |

| POWER OF FAN (KW) |

35 |

75 |

11 |

15 |

18 |

20 |

22 |

25 |

| STEAM CONSUMPTION IN KG/HR |

40 |

75 |

150 |

185 |

240 |

300 |

360 |

600 |

|

|

|

|