Sugar syrup preparation cum batch mixing vessels

|

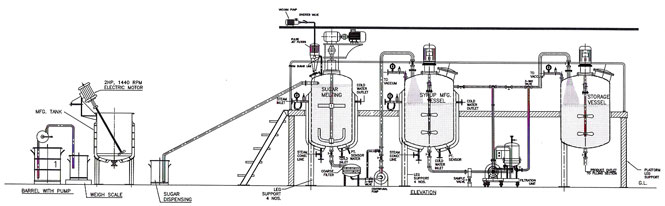

The Liquid Syrup Manufacturing Plants are ideal tools for the pharmaceutical industry for the production of Oral Liquids. Majority of Liquid Oral Syrup are sugar based & this sugar syrup is prepared using hot mix technology. Broadly end product is wither a blend of various ingredients including drugs i.e. Cough Syrup, Health tonic etc. or dispersed phase of ingredients i.e. Antacids, Pediatric suspensions. Therefore designing of entire Liquid Syrup plant is done to take care of its versatility for both Blend & dispersed phase end product. Also quality is governed by level of automation & well GMP design of plant. Liquid Oral manufacturing systems comprises of equipment for automated sugar transfer, double jacketed and non jacketed vats for sugar syrup preparation, compounding / ingredient mixing and storage with product distribution piping. The range covers capacities from 500 to 15000 Liters with various options in top and bottom entry agitators for mixing and homogenizing of clear syrups and suspensions. We offer a range of precision engineered inverter syrup sugar solution, which have been designed after extensive study to automate and prepare continuous sugar syrup.

Liquid Manufacturing Plant consist the following equipments and accessories:

- Sugar Syrup Vessel

- Pre-filtration unit

- Manufacturing Vessel

- Filtration unit

- Storage Vessel

- Control Panel

- Product Piping

- Working Platform

BASIC DESIGN FEATURES & OPERATION

- Entire plant consist of a closed circuit manufacturing facility from feeding of Sugar / Water Phase to loading the Volumetric Liquid Filling Machine.

- The Sugar and Water, are load with vacuum system or by mechanical system or manually.

- The Sugar Syrup Vessel is supplied with high speed stirrer & electrical heating ( In small model ) / steam heating facility (In bigger size model ).The sugar syrup is prepared at required temperature & are transferred to Manufacturing Vessel by vacuum or by transfer pump.

- The product during emulsion formation is re-circulated through In-Line Homoginizer or Liquid Transfer Pump. (Optional Facility)

- The Pump also discharges the product in the Storage Vessel.

- The Storage Vessel is then taken to the filling area ( if it is small capacity ) and is connected to again Liquid Transfer Pump. Or Storage Vessel remain fixed ( In bigger size) & pump transfer the Liquids in the float tank which is connected with filling machine.

- The entire Plant can be operated by centralized operating panel by one operator.

SALIENT FEATURES

- The Plant is designed to be operated only by one operator and one helper to reduce cross contamination & higher automation

- All material transfers are done by vacuum or by transfer pumps.

- All the vessels are CGMP (paint free construction) with gaskets used are of silicon (food grade).

- All contact parts are of S.S. 304 quality material (SS316 provided on demand) & finished to class 4B (Mirror) finish and are crevice free.

- The entry of stirrer & high speed emulsifier are from top. In-line Emulsifier (as per customer choice) provided on demand. (Optional)

- All vessels are suitable for internal pressure of 1 Kg. / Sq. cm. and hence can be sterilized.

- All pipes, pipe fittings and valves are of SS304 / SS316 ( as per customer requirement ) seamless quality, internally electro polished, with tri-clover ended joints. Bottom valves are zero dead pocket type with pneumatic actuation also.

- The entire plant is equipped with CIP & SIP connections, so that customer can use these facility, if have CIP & SIP equipment.

- All values of temperature & time of the plant are indicated digitally on the control panel. Ampere indicates on Ampere meters.

- A micro processor based automatic operating plant can be designed as per requirement. (Optional)

- All the inlet & outlet connections are provided with tri clover joints, which are very easy for cleaning & replacement.

- Refractrometer, Temp. Sensor, Level sensor, Conductivity sensor, PH sensor are provided for higher standardization of processing module.

- Load cell duly calibrated with PLC interfacing are provided for accurate results & closed adherence to batching system.

KEY BENEFITS

- Automatic and continuous process

- Consistent product quality achieved

- Energy efficient system

- Man power saving achieved and human errors eliminated

- Clean and hygienic environment

- High productivity achieved - due to save in man power

- Cost saving achieved due to man power savings and elimination of handling losses

|

|

|

|

|