- INTERTECH TECHNOLOGIES PVT. LTD.

Engineers to Healthcare Industry®

| |

APPLICATION |

|

Film and / or Sugar Coating applications on uncoated Tablets / Granules/ Pellets/ Food Products.

|

WORKING PRINCIPLE

The Hexagonal Pan welded with conical ends is mounted horizontally within a closed enclosure with suitable mouth opening for tablets loading and unloading. The pan is having centrally deburred, electro polished, triangular pitched perforated shell to ensured the hot air flow capacity. All tables which are loaded in pan gets sprayed by coating liquid meanwhile under the action of air exhaust and negative pressure, hot air is supplied on the bed of tables. |

|

| |

|

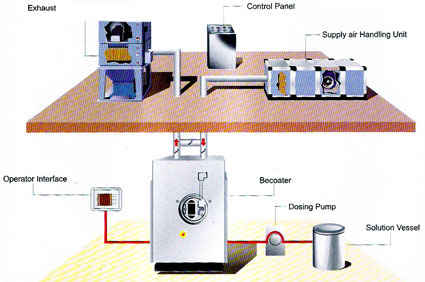

| MAIN COMPONENTS: |

|

- Inlet Air Handling Unit

- Air Inlet Filter Path

- Pre-Filters

- HEPA Filters

- Dehumidifier

- Fan details for Incoming Air.

- Heating Coil Details

- Hot Air Inlet Duct Work

- Main Coating Unit

- Solution Spraying Unit

- Peristaltic Pump

- Spray Gun

- Exhaust Unit

- Blower Details

- Exhaust Duct work

- Exhaust Damper

- Scrubber

- Dry Scrubber

- Wet Scrubber (Optional)

- WIP

|

|

| PERFORMANCE & FEATURES

- All operations can be finished the operating panel PLC Based. The main machine is reliable & stable in performance.

- Automatic airless spray gun such as Walther pilot, DeVILBISS ACG are used with Single stage or multi stage peristaltic pumps for uniform flow rate.

- Telescopic spray nozzle manifold can be withdrawn from pan by pneumatic actuation for easy change over & cleaning.

- Nozzles are replaced by Distribution rake for sugar coating & connected to high pressure pump

- Air Handling unit with HEPA filters, Dehumidification coil is provided for temp., air & humidity control

- Built in WIP system consisting of High pressure pump, Wash nozzles on the spray arm & outside the pan is provided. Automated WIP protocol controlled thru PLC is also available

- Comprehensive online status Reports, Result summaries of Alarms / controls ensures validated coating process

- Option of higher management interface i.e. SCADA with PLC Based software also provided

- Significant process parameters display like Humidity Rh/ Dew point Sensor, Velocity of air by Velometer, Temp. of Tablet bed thru PT-100, Flow rate of dispensed liquid thru flow meter, cleanliness of air thru pressure transmitter are also online available.

Technical Specifications |

MODEL |

300 |

600 |

900 |

1200 |

1500 |

| Pan Diameter |

mm |

300 |

600 |

900 |

1200 |

1500 |

| Working capacity* |

kgs |

0.5 to 1 |

10 to 15 |

50 to 80 |

100 to 150 |

250 to 275 |

| Pan Drive Motor |

hp |

1.0 |

1.0 |

2.0 |

5.0 |

7.5 |

Supply Air Blower

Motor |

hp |

0.5 |

1.0 |

3.0 |

5.0 |

7.5 |

| Exhaust Blower Motor |

hp |

1.0 |

2.0 |

5.0 |

7.5 |

10.0 |

| Wash Pump Motor |

hp |

0.5 |

1.0 |

1.0 |

1.0 |

1.0 |

| Supply Air Blower |

cfm |

200 |

300 |

1250 |

2500 |

5000 |

| WG Pressure |

inch |

4 |

4 |

4 |

4 |

7 |

| Exhaust Blower |

cfm |

300 |

450 |

1500 |

3000 |

5500 |

| WG Pressure |

inch |

6 |

8 |

8 |

8 |

10 |

| Steam Consumption** |

kg/hr |

20 |

50 |

120 |

240 |

350 |

| Heating Range |

°C |

25-85 |

25-85 |

25-85 |

25-85 |

25-85 |

| Spray Nozzles |

Nos. |

1 |

1 |

2 |

3 |

4 |

| Solution Vessel |

Itrs. |

2 |

35 |

75 |

75 |

100 |

| Pneumatic Agitator |

hp |

0.05 |

0.32 |

0.32 |

0.32 |

0.55 |

| Overall Dimensions |

L |

800 |

1200 |

1350 |

1660 |

2370 |

| (mm) |

B |

700 |

1100 |

1350 |

1610 |

2000 |

| H |

1400 |

1800 |

1800 |

2050 |

2150 |

|

|

|