- INTERTECH TECHNOLOGIES PVT. LTD.

Engineers to Healthcare Industry®

WFI Storage and Looping System

| |

APPLICATION |

|

Pure steam generator with WFI

generation capability, WFI storage

and WFI distribution system with

hot and tempered loops.

WFI generation with two WFI storage

and distribution loops.

|

|

|

| |

WFI storage and distribution systems are custom designed to meet the specific requirements of Injection manufacturing application & also based on application demand. WFI storage & related looping is always designed as per consumption & timely demand of WFI in entire injection manufacturing plant. There is a great demand of optimization of water demand along with validation adherence so that cost of assemble, start up is reduced.

Documentation for all components is also incorporated into a comprehensive turnover package. Our substantial experience is WFI looping management & its erection has resulted in its least deviation from PQ (Process Qualification) parameters. This WFI looping system typically include :

Multiple-effect still.

- Pure steam generator.

- WFI tank with spray ball.

- WFI distribution pump.

- Sanitary Heat exchanger and utility valves.

- Vent filter.

|

|

Main Instrumentation include:

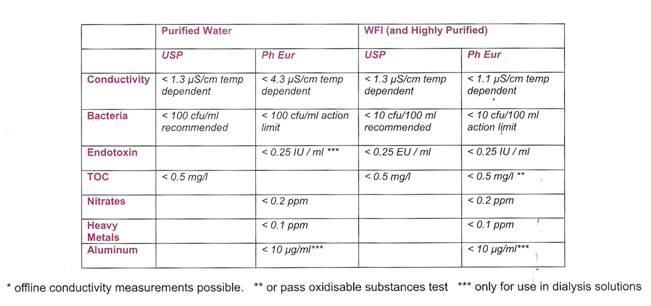

- TOC analyzer(s).

- Conductivity monitors.

- Sanitary valves.

- WFI tank level control.

- Pressure transmitters.

- Flow transmitters.

- Cooling and heating control loops.

- Tank level control.

- Temperature monitoring.

|

Construction Features:

- Material of the parts connected with the water – AISI 316 L

- Roughness of inner surface - < 0,8 µm

- Joint – Tri – Clamp

- Welding method – orbital welding using pure argon not filling cable (manual welding only in inaccessible place)

- Test method – endoscopy (10 % from orbital joint & 100 % from manual joint)

- All tubes & pipe are Electropolished & seamless

- All fittings are TC or DIN standards .

|

|